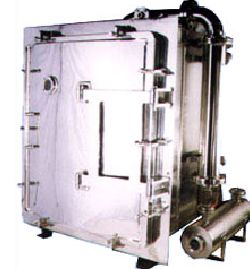

Vacuum Tray Dryer are used where heating and drying are essential parts of manufacturing process in industries such as Chemicals, Dye stuff, Pharmaceutical, Food Products, Colors etc. Vacuum Tray Dryer is suitable for drying of thermal sensitive material easily deteriorated under higher Temperature. It eliminates configuration damage of the drying materials.

Bodies may be of cylindrical or rectangular cross section. Both shelves and body are heated (the body to prevent internal condensation) with controlled circulation of hot water, steam or dia thermic fluid. Vacuum is drawn through large diameter ducts to minimize pressure drops and produce minimum working pressures. Both rotary and static dryers can be supplied with the following Optional ancillaries.

VTD - Vacuum Tray Dryers are used to heat and dry material under vacuum drying and drying materials due to high toxic contents, nature, heat sensitive. Vacuum Tray dryers use for API pharmaceutical, Herbal, chemical & foodstuff.

Vacuum Tray Dryer is a static type of dryer used in various industries under vacuum atmosphere to dry temperature sensitive materials as well as pharmaceutical and allied products. It gives complete drying and vaporization of moisture of the product. We at Bhagwati Pharma are manufacturer of Vacuum Tray Dryer. The vacuum tray dryers are been customized according to the clients specification and the available capacities ranges from 6 to 96 trays per batch.

They are suitable for various purposes that includes pharmaceutical, Herbal, chemical & foodstuff.

Vacuum Tray Dryer works on the principle of conduction considering the vacuum conditions. There are several shelves placed under which products are placed. Top shelves gives proper heating and helps to prevent dried powder from escaping into the solvent extraction system. Baffles are been placed between the shelves. It contains an inlet and outlet nozzle both are connected to its own header throughout its own nozzle

Efficient heat sensitive

Vacuum Tray dryers – VTD

| No. Of Trays | 3 | 6 | 12 | 24 | 36 | 48 | 96 |

| Capacity in Kg | 3-5 | 12-18 | 25-35 | 50-75 | 75-100 | 100-150 | 200-300 |

| Tray volume in Ltrs /Capacity in Kg | 5/1-1.5 | 10 /2-3 | 10/2-3 | 10/2-3 | 10/2-3 | 10/2-3 | 10/2-3 |

| Tray size : L W H in mm | 406x406x31 | 812x406x31 | 812x406x31 | 812x406x31 | 812x406x31 | 812x406x31 | 812x406x31 |

| No. of Heating Shelfs | 4 | 7 | 7 | 9 | 13 | 17 | 17 |

| Shelf size in mm | 430x430 | 430 X835 | 835x835 | 835x1259 | 835x1250 | 835x1250 | 1250x1650 |

| Distance between shelves in mm | 100 | 100 | 100 | 100 | 100 | 100 | 100 |

| Trays on each self | 1 | 1 | 2 | 3 | 3 | 3 | 6 |

| Condenser | 0.2m2 | 0.5 m2 | 0.75m2 | 1m2 | 1.5m2 | 2m2 | 3m2 |

| Receiver | 10Ltrs | 25 Ltrs | 50 Ltrs | 75 Ltrs | 100 Ltrs | 150 Ltrs | 250 Ltrs |

| H.W. Distribution Pipes | 1½” | 1½” | 1½” | 1½” | 1½” | 1½” | 2” |

| Door Gasket (Silicon) | 16mmSQ | 16mmSQ | 16mmSQ | 16mmSQ | 16mmSQ | 16mmSQ | 16mmSQ |

| No. of Door Bolts (Φ40) | 4 | 6 | 8 | 10 | 12 | 12 | 14 |

| Design Temperature : 1500C, TESTING : The vacuum dryer shelves are hydro-tested 5 Kg/Cm2 in Assembled condition. The vacuum chamber is tested for full vacuum. |

|||||||